Unifire AB of Sweden is a pioneer and global leader in advanced robotic nozzle technology and Autonomous Robotic Fire Suppression (ARFS) systems. The Swedish flagship product, FlameRanger™, has been transforming industrial fire protection since its debut in 2010. Over more than a decade of continuous in-house development, FlameRanger has matured into the most advanced and versatile ARFS system on the market, trusted in critical environments across 5 continents.

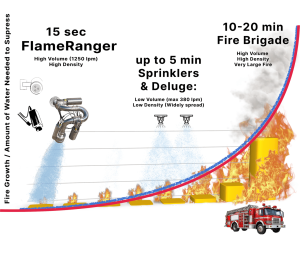

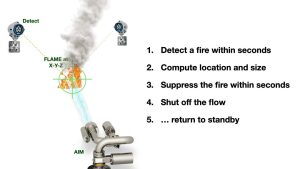

Traditional fire suppression systems—such as sprinklers, deluge systems, and even fire brigades—suffer from slow response times, poor targeting, and often excessive water damage. In contrast, FlameRanger detects, locates, tracks, and suppresses fires autonomously—typically in under 15 seconds—by combining high-precision robotic nozzles (aka “fire monitors” or “water cannons”) with industry-leading flame detection technologies, including IR3 flame detectors, thermal imaging cameras, video analytics and others.

Unlike fixed spray systems that indiscriminately soak large areas, FlameRanger intelligently directs a powerful, high-volume stream of water or foam (typically 1250+ LPM) directly at and around the source of the fire. Once the fire is extinguished, the system automatically shuts off to prevent water damage and reduce environmental impact. If the fire reignites or a hot spot flare up, FlameRanger will detect it and resume suppression without delay.

A key feature that sets FlameRanger apart is its open architecture. The system is vendor-agnostic and can integrate with virtually any fire detection brand or technology. It can also combine multiple systems simultaneously to enhance detection speed, accuracy, and redundancy. This flexibility makes FlameRanger ideal for both new installations and retrofit applications where existing infrastructure is in place.

FlameRanger is also highly modular and scalable. Systems can operate independently or as coordinated networks across large facilities, with multiple nozzles responding intelligently to a single fire event. The system’s programmable logic allows for complex rules and coordinated response scenarios tailored to each installation’s unique risk profile.

Despite its full autonomy, FlameRanger systems always allow for manual override and remote control—before, during, or after automatic deployment. Human operators can take control of the monitor at any time via joystick, Unifire’s ONE App™ (iOS/Android), or through the secure ONE Web™ interface from anywhere in the world. This capability adds an extra layer of safety, enabling proactive suppression in response to smoke, abnormal heat, or evolving threats not yet flagged by automated detectors.

FlameRanger’s built-in web server enables remote commissioning, updates, and diagnostics, eliminating the need for on-site servicing in most cases. All remote access features are included in the system with no recurring software fees.

These systems are increasingly being adopted in high-risk industries such as:

- Waste & Recycling Facilities, where spontaneous combustion and lithium-ion battery fires are common.

- Battery Energy Storage Systems (BESS), where early suppression is critical to prevent thermal runaway.

- Aircraft Hangars, where precision suppression avoids collateral damage to high-value aircraft.

- Cement Plants, chemical facilities, military installations, and tunnels, where every second counts.

The ARFS sector is growing rapidly, and FlameRanger is leading the way. FlameRanger offers a strategic edge in risk management, operational continuity, and environmental responsibility.

In a world where industrial fires can escalate within seconds, Unifire’s FlameRanger stands as a transformative solution, providing real-time protection with unmatched intelligence and flexibility.

To learn more, visit: www.unifire.com