Instrotech, local distributor of process control instrumentation and specialised systems, has on offer two products specifically for application in the measurement and control of temperature, the Optris CSmicro LT pyrometer, for cement manufacture and Optris PI400 infrared camera.

CEMENT MANUFACTURE and Optris CSmicro LT pyrometer

Temperature is a critically importance component in the process of making of concrete, and specifically, the importance of controlling the temperature before the concrete is deposited. Optimal temperature of the concrete must fall within the range of +5°C and +55°C, a factor which greatly influences the final characteristics of concrete and performance (cracking, resistance and wear and tear). Concrete temperature is directly related to the development of strength and fresh concrete can be damaged when exposed to very low or very high temperatures.

Key factors to control during the pouring of concrete related with temperature:

- Warm weather affects speed limits evaporation

- Cold weather inhibits the hydration process

Optris’ CSmicro LT is equipped with an innovative, miniaturised stainless steel measuring head, the optimally suited for installation in limited spaces. Its small size and its temperature resistance up to 120°C make the mechanic integration of the measuring head especially cost-efficient.

The intelligent LED display works optionally as alarm signal, target support, self-diagnosis or temperature-code display. The placement of electronic components within the cable allows for a high temperature resistance of the measuring head. It measures temperature in the range of -40°C to 1,030°C; the spectral range is 8 to 14 µm and the response time is 30 ms – 999 s. The unit can be optimally installed on cement pumps, mixer trucks and cement silos.

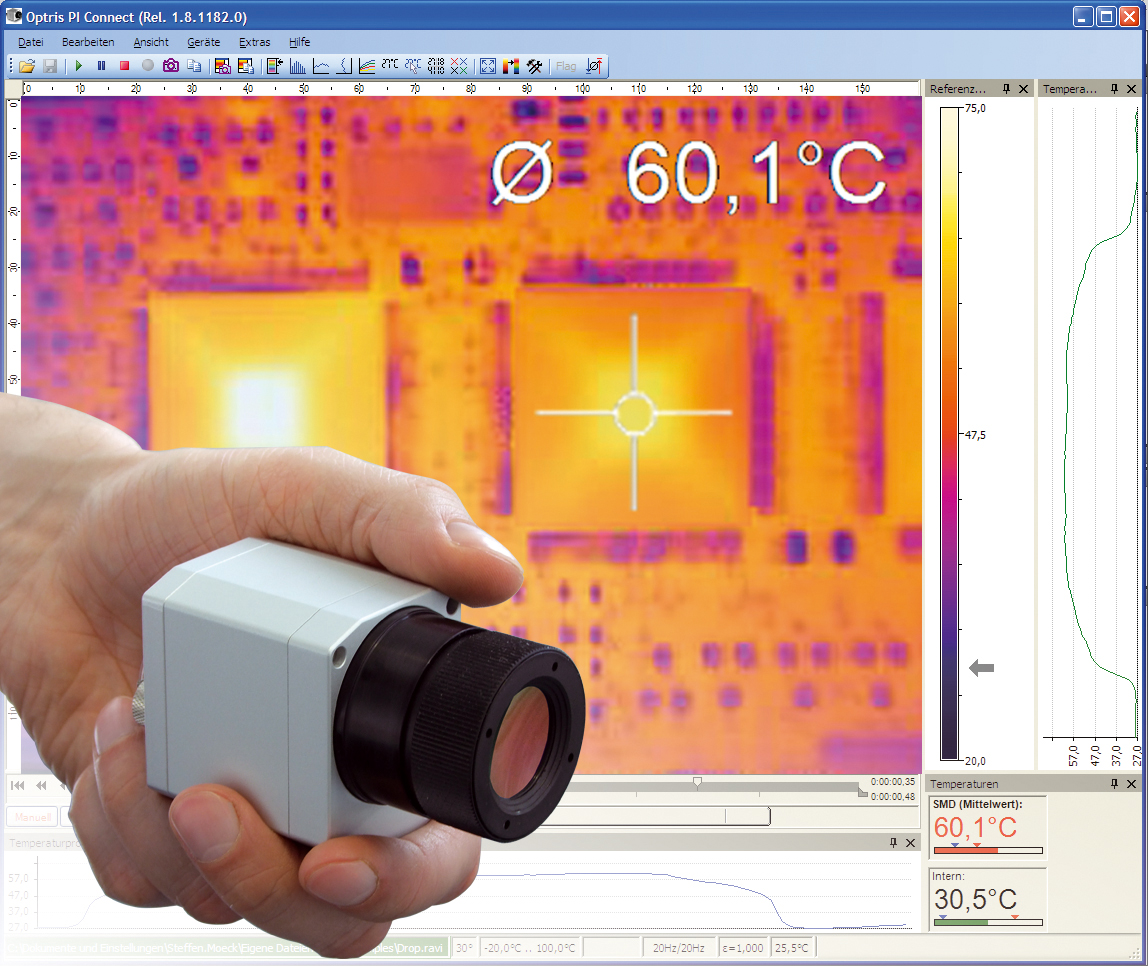

Infrared camera Optris PI 400

Optris’ PI 400 infrared camera is the smallest thermographic camera in its class. Being equipped with a measurement speed of 80 Hz and an optical resolution of 382 x 288 pixels, it offers real-time thermographic images in high speed.

The compact and high-performance infrared camera has a temperature range of -20°C up to 900°C, with an optional upgrade to 1,500°C. It can be delivered with exchangeable optics, industrial thermal imager equipment and it comes with an extensive license-free thermography software package.

Areas of application for the thermal imagers Optris PI 400

The Optris PI 400 is employed for a variety of tasks in industry. The real-time thermographic images prove especially valuable for surveillance and quality assurance in the automotive sector, plastics, and in the semi-conductor as well as photovoltaic industries.

Due to this type of thermographic cameras’ high resolution and the reaction speed, surveillance and measuring of manufacturing processes that include moving objects poses no problem. Possible areas of application are process automation of measurement in rotary kilns or measurement of large amounts on conveyor belts during batch processes.

The IR camera also plays an important role in medical diagnosis and prevention where it detects the slightest of temperature differences. It can even highlight veins under the skin due to its brilliant optical resolution of up to 40 mK.

Important Specifications

- Temperature range: -20°C to 900°C

- Spectral range: 7.5 to 13 µm

- Frame rate: 80 Hz

For more information on the full range of Optris equipment and sensors for industrial temperature control, contact Instrotech on 011 462 1920 or sales@instrotech.co.za

ENDS

Instrotech – a Comtest Group Company – distributes and manufactures a range of process control instrumentation and specialized systems which are sold locally and internationally through a number of designated distributors.

For INSTROTECH – Tel: +27 11 462 1920 email: sales@instrotech.co.za

By: V Squared Marketing – Tel: +27 11 678 2227 email: vtwo@telkomsa.net

V2 12029* Optris IndTempControl CSmicro & PI400 20171107.docx

I must express thanks to you for rescuing me from this type of circumstance. After surfing around throughout the online world and obtaining proposals that were not productive, I believed my entire life was over. Being alive minus the answers to the problems you’ve solved as a result of your post is a critical case, and the ones that would have in a negative way affected my career if I hadn’t noticed your blog post. That expertise and kindness in controlling everything was very useful. I am not sure what I would have done if I hadn’t come upon such a stuff like this. I can also at this point relish my future. Thanks for your time very much for this professional and result oriented guide. I will not hesitate to propose your blog post to any person who needs counselling on this subject matter.

I must express some appreciation to you for bailing me out of this issue. As a result of scouting throughout the internet and finding proposals that were not powerful, I figured my entire life was well over. Living without the solutions to the problems you’ve solved as a result of your main short post is a serious case, as well as the kind which might have negatively damaged my career if I hadn’t discovered your blog. Your own personal understanding and kindness in playing with almost everything was important. I am not sure what I would have done if I had not come across such a solution like this. It’s possible to at this point look ahead to my future. Thanks a lot so much for this impressive and effective guide. I will not hesitate to propose your web page to anyone who needs and wants tips about this area.

I would like to show my thanks to the writer just for bailing me out of this type of predicament. After browsing through the world-wide-web and obtaining methods which are not powerful, I assumed my entire life was over. Being alive devoid of the solutions to the issues you’ve resolved by way of your entire report is a critical case, and those that would have in a wrong way damaged my career if I had not discovered your web blog. Your ability and kindness in handling all the pieces was excellent. I am not sure what I would’ve done if I hadn’t encountered such a point like this. I can also at this time relish my future. Thank you very much for this specialized and sensible help. I will not hesitate to propose the blog to anybody who would need recommendations about this problem.

I am glad for writing to let you understand of the notable discovery my cousin’s daughter encountered going through your webblog. She figured out a good number of things, most notably what it is like to possess an excellent helping nature to make many others effortlessly have an understanding of chosen extremely tough matters. You actually exceeded visitors’ expectations. Thank you for presenting those interesting, healthy, informative and unique guidance on that topic to Mary.

I simply wished to thank you so much once again. I am not sure the things that I could possibly have created without the type of hints shown by you about such area. Certainly was a terrifying setting in my circumstances, however , being able to view a skilled strategy you solved it forced me to cry over gladness. I will be grateful for this information and in addition hope that you are aware of an amazing job you happen to be accomplishing teaching many people via your web site. Most probably you’ve never met all of us.