Plastic Paint Bucket Molding Line|Paint Bucket Plastic Injection Molding Machines-DKM High Speed Paint Bucket Molding Technological Innovation

keywords:Plastic Paint Bucket Injection Molding Machine,Plastic Paint Bucket Molding Line,One Stop Service For Paint Bucket,High Speed Paint Bucket Molding Technological Innovation

description: DKM has realized producing one 20L IML plastic paint bucket by DKM 600HH high speed injection molding machine in a cycle time of 15 seconds, thanks to it succeeded in plastic paint pail high speed molding technology innovation.

Main headings

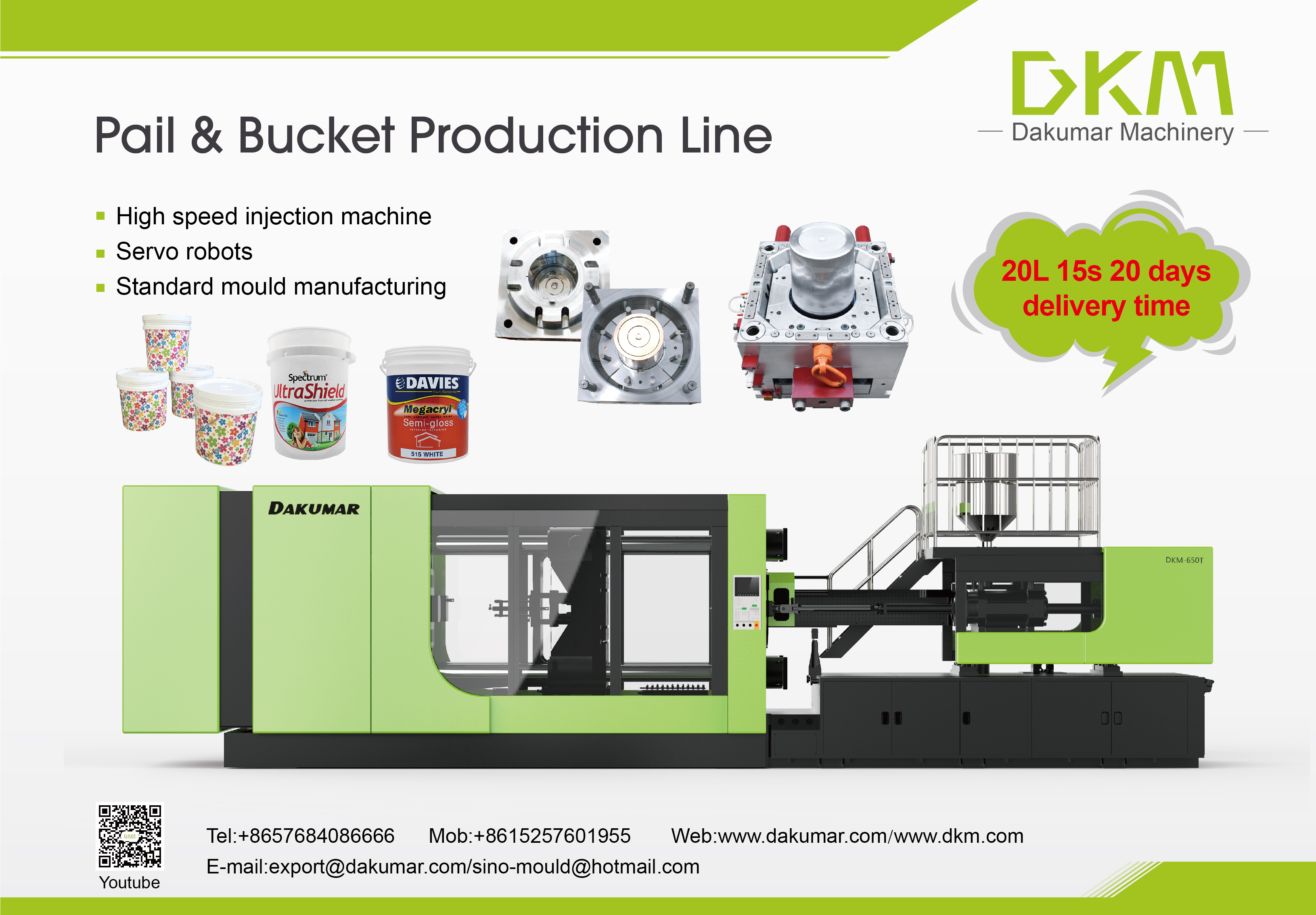

DKM Innovation: 20L IML Plastic Paint Bucket Molding Line At Cycle Time 15 Seconds

Sub-headings: Unlocking your full potential of production with our one stop service

Dakumar Machinery (DKM) has achieved an innovation of IML plastic paint bucket high speed molding line – automatic production line – at faster and faster but stable running, help customers stay on track for success as DKM joins them on the road to the better future of plastic paint pail molding.

20L IML Plastic Bucket Molding Line Details

A DKM 600HH high speed injection molding machine fully automatically produces one 20L plastic paint bucket made from HDPE in a cycle time of 15 seconds! Furthermore, the plastic bucket surface printing takes place within the injection molding cycle by method of IML system. It could also remove the buckets and set them down in a conveyor (for further cooling) and then move them to next process station.

| Items | Specification | |

| Mould | 20L Plastic Paint Bucket Mould | mould cavity number: 1

core and cavity steel: P20 + Beryllium Copper runner: Anole 1 tip hot runner mould size: 700*700*902mm |

| Machine | DKM-600HH | High speed injection molding machine – highly efficient machine designed for thin wall plastic buckets.

-Parallel operation to realize material charging, mould opening and ejection at the same time -High speed injection -High precision single cylinder injection system -High response servo system -European advanced computer controller -Using world famous brands spare parts in electric and hydraulic elements… |

| Automatic system | IML System | In Mold Labeling equipment suitable for efficient production with higher safety protection. |

| Auxiliary equipment | Auto Loader

Air Chiller Air Compressor set Mixer … |

Help to deliver consistently high product quality & maximum machine availability. |

How could DKM offer the high performance 20L plastic paint bucket molding line? It thanks to its continual researching and development on plastics high speed injection molding technology according the more than 25 years field-specific experiences. Based on the mission of maximizing the value of plastic molding activities, DKM has been committed to providing the most efficient and fastest paint pail production turnkey project – nearly 100 UNITES – for domestic and foreign customers.

DKM One Stop Service

Project Audit (such as for the most suitable part design, mould solution and machine model…)

Automation or Intelligent System Suggestion

Machine Assembling Foundation Layout Assistance

Operator Train before Machine and Moulds Shipment

Hunting Chinese Engineer or Management Officers

Machine & Mould Installation & Running

On Site & Online Training

DKM is advancing the response of our business processes and services globally. So its customers benefit from the DKM turnkey solutions that enable them to boost quicker production, higher value added, and get more stable running reliability from the complete guidance.

Start Your Plastic Paint Bucket Project by DKM

Planning to start your plastic paint bucket manufacturing business? Welcome to contact DKM now for quick start! The perfect one stop service for paint bucket molding lines is here for you with DKM professional team.

I have to express some appreciation to this writer just for rescuing me from this particular trouble. Just after looking through the online world and finding views that were not productive, I believed my entire life was over. Being alive without the presence of approaches to the issues you’ve solved as a result of your good guide is a crucial case, as well as those which might have in a negative way damaged my entire career if I had not come across your blog post. Your actual skills and kindness in dealing with every aspect was important. I am not sure what I would’ve done if I hadn’t come across such a stuff like this. I can also at this point relish my future. Thank you very much for your reliable and amazing help. I will not think twice to refer the sites to anyone who should receive guidelines about this matter.

I want to show my thanks to you just for rescuing me from this particular circumstance. Right after exploring throughout the internet and seeing solutions that were not beneficial, I thought my life was gone. Living without the presence of answers to the issues you’ve solved through your entire review is a serious case, as well as ones which might have adversely damaged my career if I hadn’t come across your web page. Your own training and kindness in dealing with everything was helpful. I am not sure what I would’ve done if I hadn’t encountered such a solution like this. I’m able to at this moment relish my future. Thanks for your time so much for this high quality and effective guide. I won’t think twice to suggest your web sites to any person who desires support on this subject.

I in addition to my friends were found to be digesting the excellent ideas on your web site and then then came up with an awful feeling I never expressed respect to the site owner for those tips. The boys were certainly happy to read through all of them and have undoubtedly been making the most of those things. We appreciate you really being considerably thoughtful and then for settling on some great subject matter millions of individuals are really eager to discover. My very own sincere regret for not expressing appreciation to sooner.

My husband and i have been absolutely relieved Michael managed to conclude his studies through the precious recommendations he made out of the site. It is now and again perplexing just to happen to be releasing hints that many some other people might have been making money from. And now we recognize we need the blog owner to appreciate for that. The illustrations you made, the easy site navigation, the relationships your site aid to promote – it’s got everything impressive, and it’s aiding our son and our family reckon that this idea is excellent, which is truly mandatory. Thanks for all the pieces!

My husband and i ended up being now cheerful when Jordan managed to finish up his reports while using the precious recommendations he received while using the web site. It’s not at all simplistic just to continually be giving for free guides other people might have been trying to sell. And we discover we have got the website owner to give thanks to for that. The entire illustrations you made, the easy site navigation, the friendships your site help to create – it is all terrific, and it is aiding our son and us reason why the idea is amusing, and that is extremely mandatory. Thanks for the whole thing!

I am just writing to make you know of the cool experience our girl undergone using yuor web blog. She discovered some details, most notably what it’s like to possess a very effective teaching heart to get many others smoothly completely grasp various complicated subject areas. You actually did more than her desires. Thank you for offering those valuable, healthy, educational and in addition fun tips about your topic to Evelyn.