Industrial operations continually face a simple truth; equipment failures cost more than most organizations realize. Traditional condition monitoring approaches, while better than nothing, often miss the early warning signs that could prevent expensive breakdowns. Reliable wireless IoT vibration sensors are changing this reality by providing continuous, accurate data that helps maintenance teams act before problems become disasters.

Bridging the Gap Between Legacy Maintenance and Digital Innovation

The Hidden Costs of Traditional Condition Monitoring

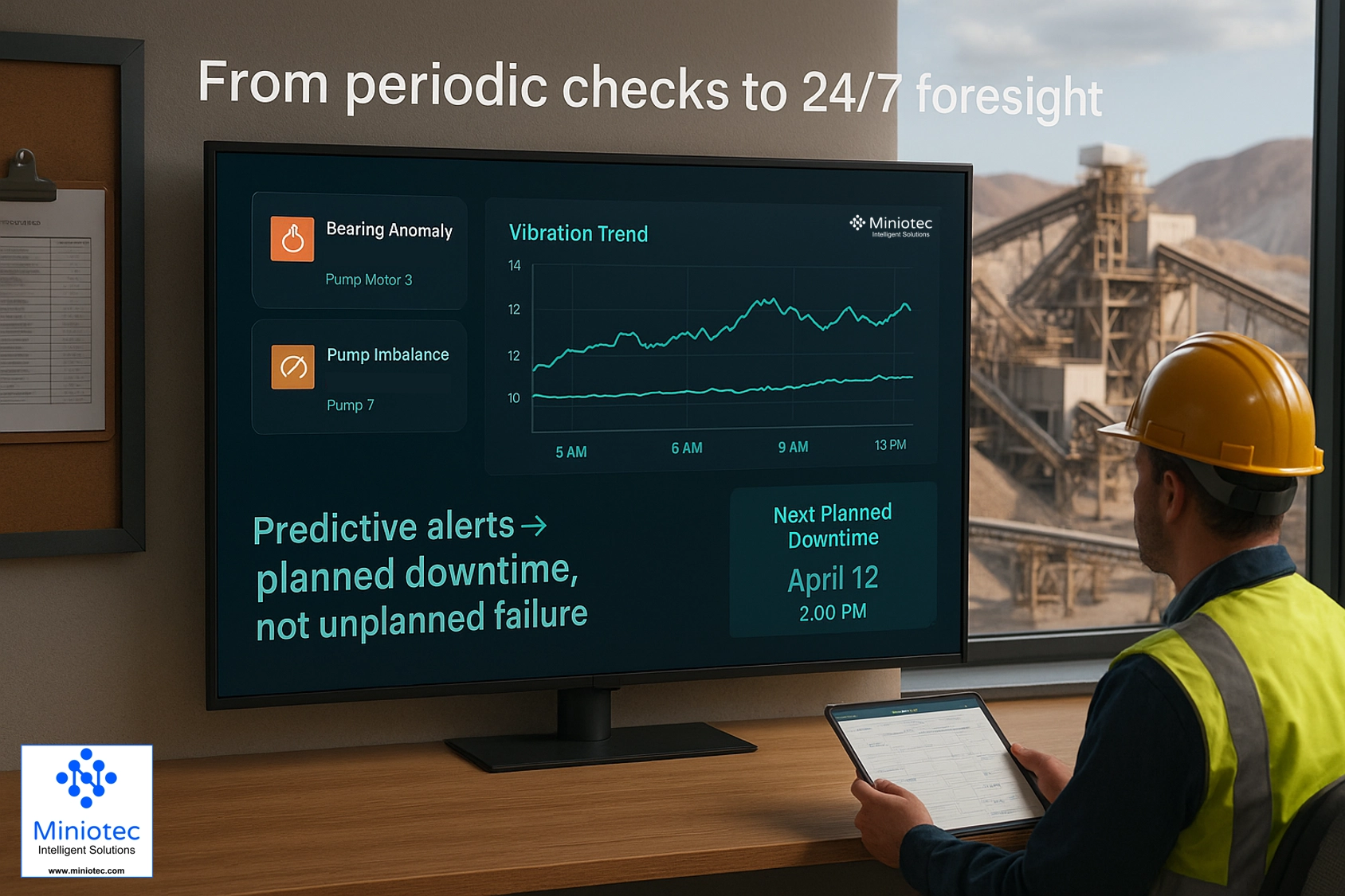

Manual vibration monitoring has served industries for decades, but its limitations are becoming harder to ignore. Technicians walking routes with handheld devices can only capture snapshots of machine health at specific moments. Between these periodic checks, equipment conditions can change dramatically without anyone noticing.

The real problem isn’t just what these manual methods miss. It’s the resources they consume. Skilled workers spend hours collecting data from hundreds of assets across a facility. Travel time to remote or hard-to-reach equipment adds up quickly. Meanwhile, the data they gather sits in spreadsheets waiting for analysis, often too late to prevent failures.

Remote condition monitoring through wireless vibration monitoring systems solves these problems by providing constant surveillance. Sensors work 24/7, capturing changes as they happen. This shift from periodic sampling to continuous monitoring means teams can spot developing issues days or weeks earlier than manual methods allow.

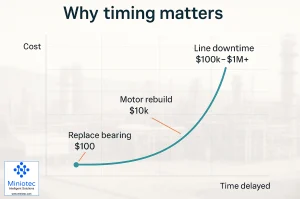

Why Timing Matters: The Exponential Cost of Delayed Action

When maintenance teams know a bearing is starting to fail but delay replacement, they’re making a costly bet. Research and experience show that the expense of fixing equipment failures grows exponentially with each delay. A $100 bearing left in service too long can damage a motor, leading to a $10,000 repair. Wait longer, and that motor failure might damage connected equipment, multiplying costs again. And the costs associated with lost production will greatly amplify the impact on an organisation’s bottom line.

This pattern, known as the inverse-square rule for deferred maintenance, demonstrates why early detection matters so much. With predictive maintenance sensors providing real-time alerts, teams can schedule repairs during planned downtime, order parts in advance, and avoid the cascade of failures that turn minor issues into major shutdowns.

What Makes a Vibration Sensor Truly Reliable

Improving System Reliability Through Gateway-Free Architecture and LTE Connectivity

Not all wireless vibration sensors work the same way. Many older or inferior systems require gateways to collect and transmit data, adding complexity, cost, and potential failure points. These gateways need costly installation, configuration, and maintenance of their own.

Modern IIoT vibration sensors that connect directly via LTE networks eliminate these complications. Like smartphones, they link straight to cellular networks without intermediate hardware. This gateway-free vibration monitoring approach means installation takes minutes instead of months. There’s no trenching for cables and power, no gateway placement decisions, and no network configuration headaches.

For operations with assets spread across large areas or multiple sites, this simplicity becomes a major advantage. Each sensor operates independently, so adding new monitoring points requires nothing more than mounting the device and activating its connection.

Multi-Parameter Monitoring Beyond Vibration

True equipment health monitoring requires more than vibration data alone. Temperature changes, acoustic signatures, and other parameters provide context that helps distinguish real problems from normal operating variations.

Advanced wireless condition monitoring systems integrate multiple sensors into a single device. They track vibration along three axes, measure surface temperature, capture acoustic emissions, and monitor magnetic flux. This comprehensive view helps differentiate between actual bearing failures and temporary changes caused by load variations or speed adjustments.

“Continuous, multi-parameter sensing turns maintenance from periodic ‘what happened’ checks into a living risk register that auto-prioritises action before failure.”

Data Security and Operational Continuity

Industrial operations rightfully worry about cybersecurity when connecting equipment to networks. Reliable condition monitoring for harsh environments must include robust security features that protect sensitive operational data.

Modern IIoT systems address these concerns through encrypted data transmission, secure authentication, and regular security updates. Organizations can also implement network segmentation strategies that isolate monitoring systems from critical control infrastructure.

Business Impact: Beyond Equipment Uptime

Optimizing Maintenance Resource Allocation

Real-time vibration analysis changes how maintenance departments allocate their resources. Instead of following fixed schedules regardless of actual equipment condition, teams can focus on assets that truly need attention. This condition-based approach reduces unnecessary maintenance while catching real problems earlier.

The efficiency gains free up skilled workers to tackle more complex problems and improvement projects instead of routine data collection.

Safety Enhancements Through Proactive Monitoring

Equipment failures in industrial environments can pose serious safety risks. Wireless vibration sensors help prevent dangerous situations by detecting problems before they lead to catastrophic failures.

Remote monitoring also reduces the need for personnel to access hazardous locations for routine checks. Sensors installed in high locations, confined spaces, or other risky areas eliminate the need for repeated human exposure to these dangers.

Sustainability and Environmental Responsibility

Running equipment to failure wastes energy and materials. Predictive maintenance strategies supported by reliable sensors help organizations operate more efficiently. Well-maintained equipment uses less power, produces fewer emissions, and lasts longer before requiring replacement.

“LTE-native, gateway-free devices remove the hardest part—site networking—so reliability can scale as a configuration task rather than an infrastructure project.”

Positioning for Industry 4.0 and Beyond

IIoT as a Cornerstone of Digital Transformation

Wireless vibration monitoring represents an accessible entry point into broader digital transformation initiatives. The data these sensors provide becomes more valuable when integrated with other systems like CMMS platforms, historians, production schedulers, and business intelligence tools.

Organizations that implement these technologies build the foundation for more advanced capabilities. The infrastructure and experience gained through sensor deployment prepares teams for future automation and analytics opportunities.

Preparing for Next-Generation Autonomous Maintenance

As artificial intelligence capabilities continue advancing, maintenance operations will become increasingly automated. Systems will not only detect problems but also schedule repairs, order parts, and even adjust operating parameters to extend equipment life.

Organizations investing in reliable wireless vibration sensors today are taking the first steps toward this future. The data they collect trains algorithms, validates models, and builds the knowledge base that autonomous systems will require.

Industrial operations that treat asset health monitoring as a strategic priority position themselves to compete effectively as technology continues to change. The question isn’t whether to adopt these tools, but how quickly organizations can implement them and start benefiting from the reliability improvements they provide.

Article by: Miniotec